What are the 2 main types of spill kits?

Spills happen. Whether it's in a workplace, laboratory, or industrial setting, it's crucial to have the right tools to quickly and effectively address hazardous spills. This is where spill kits come into play. In this article, we will explore the two main types of spill kits, their importance, and factors to consider when choosing the right one for your needs.

Why are spill kits important?

Spill kits are an essential part of any safety protocol. They are designed to control, contain, and clean up hazardous spills to prevent further damage to the environment, property, and most importantly, to protect human health. By having spill kits readily available, you can minimize potential risks and ensure a swift response to any spill emergency.

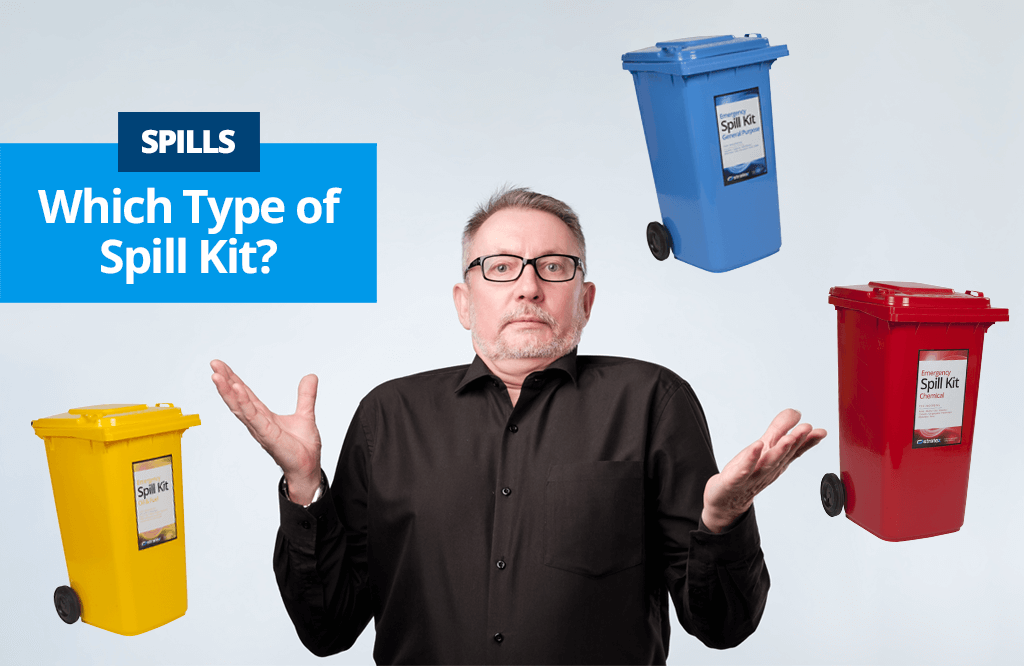

Main types of spill kits

There are two main types of spill kits: Type A and Type B. Each type is specifically designed to handle different types of spills, making it crucial to understand their characteristics and applications.

1. Type A spill kits

Type A spill kits, also known as universal spill kits, are versatile and suitable for a wide range of hazardous spills. These spills can include oils, fuels, solvents, water-based liquids, and chemicals. Type A spill kits typically include absorbents that can quickly and efficiently soak up the spilled substance. It is important to note that while Type A spill kits can handle a variety of spills, they may not be suitable for highly aggressive chemicals or corrosive substances.

2. Type B spill kits

Type B spill kits, also known as oil-only spill kits, are specifically designed to handle oil and petroleum-based spills. These kits contain absorbents that repel water and selectively absorb oils and other hydrocarbon-based substances. Type B spill kits are ideal for dealing with spills on water surfaces, as they effectively skim and absorb oil, leaving the water clean and unaffected.

Factors to consider when choosing a spill kit

- The type of substances that may be spilled in your workplace

- The size and capacity of the spill kit

- The absorbent material used in the kit

- The ease of use and accessibility of the kit

- Compliance with relevant regulations and industry standards

Benefits of using spill kits

By having the appropriate spill kit on hand, you can enjoy several benefits:

- Rapid response and containment of spills

- Minimized environmental impact

- Reduced risk to human health and safety

- Compliance with regulatory requirements

- Potential cost savings by preventing further damage

Conclusion

Spill kits are an indispensable tool in any workplace or environment where spills can occur. By understanding the two main types of spill kits, their applications, and considering the relevant factors, you can ensure that you have the right spill kit to address any potential hazards effectively. Remember, a quick and appropriate response to a spill can make all the difference in minimizing the impact and protecting everyone involved.

Frequently Asked Questions

1. What are the key differences between Type A and Type B spill kits?

The key difference lies in the types of spills they are designed to handle. Type A spill kits are universal and suitable for a wide range of spills, including oils, chemicals, and solvents. On the other hand, Type B spill kits are specifically designed to handle oil and petroleum-based spills.

2. Which industries commonly use Type A spill kits?

Type A spill kits are commonly used in industries such as manufacturing, automotive, laboratories, and warehouses, where a variety of substances may be present and spilled.

3. Are Type B spill kits suitable for all types of hazardous spills?

No, Type B spill kits are specifically designed for oil and petroleum-based spills. They may not be suitable for spills involving aggressive chemicals or corrosive substances.

4. How often should spill kits be inspected and restocked?

Spill kits should be regularly inspected to ensure they are fully stocked and in good condition. The frequency of inspection and restocking may vary depending on the specific industry, workplace, and regulations. It is recommended to have a set schedule for inspections and restocking to maintain the readiness of the spill kits.

Leave a Reply